Process Compatibility:Widely compatible with various industrial processes

Monitoring Range:Extends from -20°C to +70°C, meeting diverse environmental needs

Sampling Frequency:Up to 10 samples per second, ensuring real-time data acquisition

Operating Voltage:12V DC, ensuring reliability across different power supplies

Data Storage Capacity:Over 1 million data points, supporting extensive historical analysis

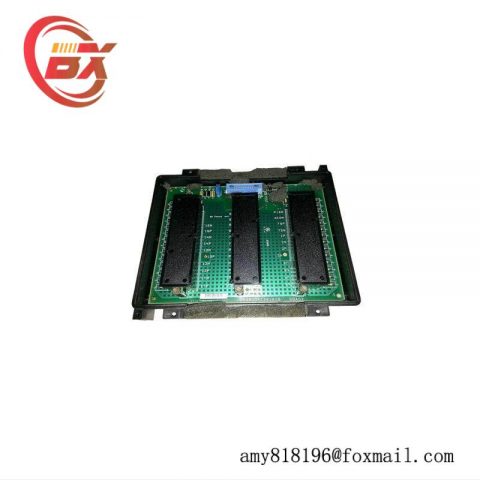

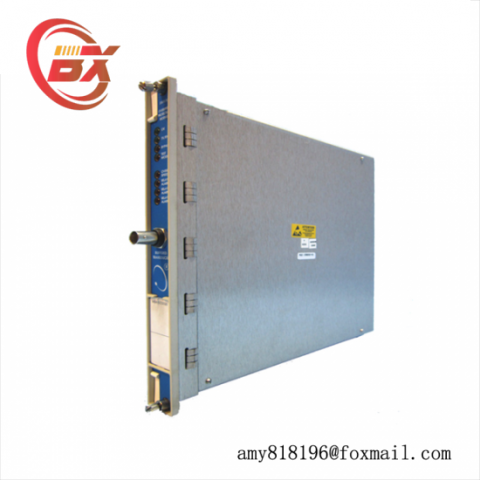

Bently Nevada 3500/22M is specifically designed for process automation, providing a robust solution for critical operations where accuracy and reliability are paramount. Its compact design ensures seamless integration into existing systems without compromising on performance.

Equipped with advanced sensor technology, this module excels in monitoring temperature, pressure, and flow rates with exceptional precision. It’s engineered to withstand harsh industrial environments, making it ideal for applications in oil & gas, chemical processing, and manufacturing sectors.

Featuring an intuitive interface and comprehensive diagnostics tools, Bently Nevada 3500/22M simplifies system setup and maintenance, reducing downtime and enhancing operational efficiency. With its high sampling frequency, users can rely on up-to-date data for informed decision-making and proactive management.

The module supports both local and remote access through Ethernet connectivity, allowing for easy integration with SCADA systems or cloud-based solutions. This facilitates real-time monitoring and historical data analysis, enabling predictive maintenance and optimizing operational performance.

Manufactured with premium materials, Bently Nevada 3500/22M ensures durability and longevity. It adheres to stringent quality standards, ensuring compliance with industry regulations and safety protocols. For businesses seeking a reliable and efficient process automation solution, this module is an indispensable asset.

There are no reviews yet.